Identifying the Components of Inventory Control and Maintenance with a Cost and Time Optimization Approach (Case Study: Mazandaran Province Water and Wastewater Company)

Keywords:

Inventory control, maintenance and repair, cost and time optimization, Mazandaran Province Water and Wastewater CompanyAbstract

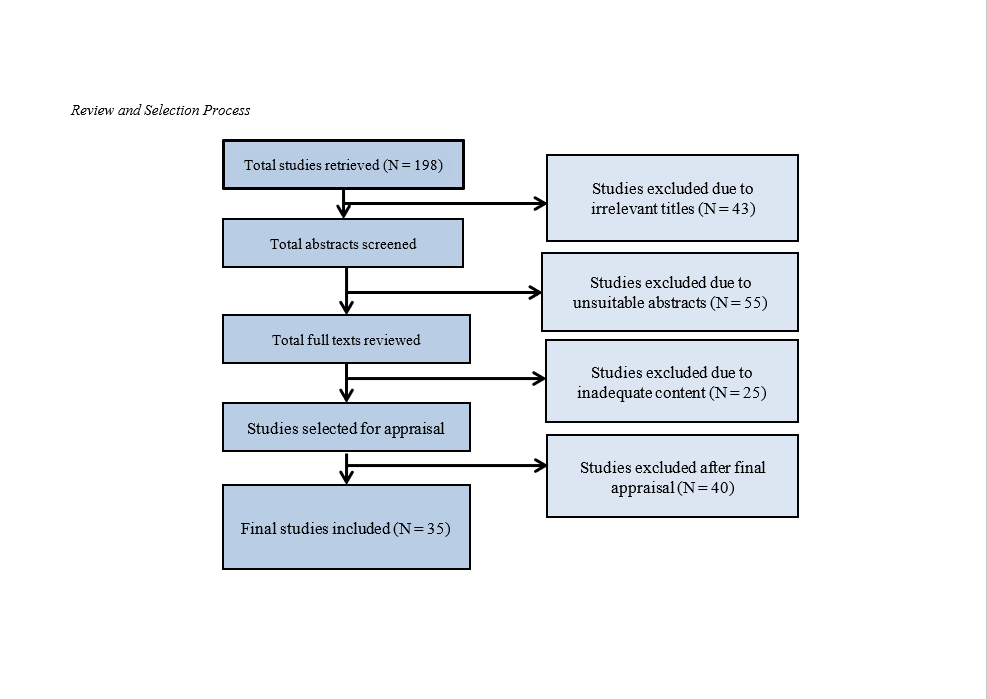

The purpose of this study is to identify the components of inventory control and maintenance with a focus on optimizing cost and time. By employing a systematic review and meta-synthesis approach, the researcher analyzed the results and findings of previous studies. Using the seven-step method of Sandelowski and Barroso, the influential factors were identified. Out of 198 articles, 35 were selected based on the CASP method. The validity of the analysis was confirmed using the Kappa coefficient, which was calculated at 0.775. The Kappa index was also used to assess reliability and quality control, indicating a high level of agreement for the identified indicators. Data collected were analyzed using MAXQDA software, resulting in the identification of six dimensions and 33 indicators for the model. To identify the components of the model, the meta-synthesis technique was applied. The identified dimensions include: inventory control, maintenance and repair, cost-related dimension, time-related dimension, technology and information systems, and planning and decision-making. Developing a comprehensive program based on risk analysis, forecasting future needs, analyzing failure trends, and allocating resources is essential for optimal management in this industry. Decision-making should be evidence-based and rely on multi-dimensional analyses to strike a balance between time, cost, service quality, and infrastructure sustainability. Stakeholder engagement, including operators, managers, engineers, and customers, in the decision-making process can facilitate a better understanding of priorities and challenges. Given the limited resources and complexity of water and wastewater service structures, the use of decision-support tools such as scenario analysis and decision support systems can enable more accurate planning and improved responsiveness in crisis situations.

References

Abdul-Malak, D. T., Kharoufeh, J. P., & Maillart, L. M. (2019). Maintaining systems with heterogeneous spare parts. Naval Research Logistics (Nrl), 66(6), 485-501. https://doi.org/10.1002/nav.21864

Achamrah, F. E., Riane, F., & Limbourg, S. (2022). Spare parts inventory routing problem with transshipment and substitutions under stochastic demands. Applied Mathematical Modelling, 101, 309-331. https://doi.org/10.1016/j.apm.2021.08.029

Adabbo, G., Andreozzi, A., Iasiello, M., Napoli, G., & Vanoli, G. (2025). A multi-objective optimization framework through genetic algorithm for hyperthermia-mediated drug delivery. Computers in Biology and Medicine, 189, 109895.

Alamri, T. O., & Mo, J. P. T. (2023). Optimisation of Preventive Maintenance Regime Based on Failure Mode System Modelling Considering Reliability. Arabian Journal for Science and Engineering, 48, 3455-3477. https://doi.org/10.1007/s13369-022-07174-w

Basten, R. J. I., & Ryan, K. J. (2019). The value of maintenance delay flexibility for improved spare parts inventory management. European Journal of Operational Research, 278(2), 646-657. https://doi.org/10.1016/j.ejor.2019.04.023

Bukhsh, Z. A., Molegraaf, H., & Jansen, N. (2023). A maintenance planning framework using online and offline deep reinforcement learning. Neural Computing and Applications. https://doi.org/10.1007/s00521-023-08560-7

Cacereño, A., Greiner, D., & Galván, B. (2023). Simultaneous optimization of design and maintenance for systems using multi-objective evolutionary algorithms and discrete simulation. Soft Computing. https://doi.org/10.1007/s00500-023-08922-2

Cuartas, C., & Aguilar, J. (2023). Hybrid algorithm based on reinforcement learning for smart inventory management. Journal of Intelligent Manufacturing, 34, 123-149. https://doi.org/10.1007/s10845-022-01982-5

Delnaz, A., Nasiri, F., & Li, S. S. (2023). Asset management analytics for urban water mains: a literature review. Environmental Systems Research, 12(12). https://doi.org/10.1186/s40068-023-00287-7

Dey, B. K., & Seok, H. (2022). Intelligent inventory management with autonomation and service strategy. Journal of Intelligent Manufacturing. https://doi.org/10.1007/s10845-022-02046-4

Dinh, D. H., Do, P., & Iung, B. (2022). Multi-level opportunistic predictive maintenance for multi-component systems with economic dependence and assembly/disassembly impacts. Reliability Engineering & System Safety, 217, 108055. https://doi.org/10.1016/j.ress.2021.108055

Dursun, İ., Akçay, A., & van Houtum, G. J. (2022). Age-based maintenance under population heterogeneity: Optimal exploration and exploitation. European Journal of Operational Research, 301(3), 1007-1020. https://doi.org/10.1016/j.ejor.2021.11.038

Fakhimi Hosseinzadeh, S., Alavi Matin, Y., & Iranzadeh, S. (2023). An Innovative Multi-Criteria Classification Method for Determining Spare Parts Management Policies: A Case Study of East Azerbaijan Water and Wastewater Company. 17th International Conference on Management, Economics, and Development,

Hajej, Z., Nyoungue, A. C., Abubakar, A. S., & Kammoun, M. A. (2022). An Integrated Model of Production, Maintenance, and Quality Control with Statistical Process Control Chart of a Supply Chain. Applied Sciences, 11(9), 4192. https://doi.org/10.3390/app11094192

Hashemian, S. E., Shafahi, Y., & Moghaddasnejad, F. (2021). Life Cycle Cost Analysis of Maintenance Decisions Using Markov Prediction Model Output Based on Railway Track Measurement Machine Data. Amirkabir Journal of Civil Engineering, 53(2), 555-574.

Ingemarsdotter, E., Kambanou, M. L., Jamsin, E., Sakao, T., & Balkenende, R. (2021). Challenges and solutions in condition-based maintenance implementation - a multiple case study. Journal of Cleaner Production, 296, 126420. https://doi.org/10.1016/j.jclepro.2021.126420

Kalantari, M., Haghighat Monfared, J., & Keramati, M. A. (2020). Explaining the Requirements of a Smart Water Management System in Iran. Smart Business Management Studies, 34, 95-136.

Karabağ, O., Eruguz, A. S., & Basten, R. (2020). Integrated optimization of maintenance interventions and spare part selection for a partially observable multi-component system. Reliability Engineering & System Safety, 200, 106955. https://doi.org/10.1016/j.ress.2020.106955

Kaya, B., & Ulutagay, G. (2023). Inventory and Maintenance Optimization of Conditional Based Maintenance Using Fuzzy Inference System (F. Calisir, Ed.). Springer, Cham. https://doi.org/10.1007/978-3-031-25847-3_18

Khoshnevis, M., alami, f., & Sarraf, A. (2023). Risk analysis of water and wastewater infrastructure projects based on public-private partnership (3P) approach by combining Fuzzy Delphi (FD), FMEA and artificial fuzzy assessment (FSE) techniques. Journal of Structural and Construction Engineering, 9(11), 77-100. https://doi.org/10.22065/jsce.2022.315454.2644

Lönnrot, P. (2025). Portfolio optimization with AI: Evaluating Performance Beyond Traditional Techniques.

Maziotis, A., Villegas, A., Molinos-Senante, M., & Sala-Garrido, R. (2020). Impact of external costs of unplanned supply interruptions on water company efficiency: evidence from Chile. Utilities Policy, 66, 101087. https://doi.org/10.1016/j.jup.2020.101087

Pasupuleti, M. K. (2025). AI in Global Trade and Economics: Predictive Modeling and Quantum-Enhanced Policy Optimization. 46-58. https://doi.org/10.62311/nesx/77517

Rivera-Gómez, H., Gharbi, A., Kenné, J. P., Montaño-Arango, O., & Corona-Armenta, J. R. (2019). Joint optimization of production and maintenance strategies considering a dynamic sampling strategy for a deteriorating system. Computers and Industrial Engineering, 140, 106273. https://doi.org/10.1016/j.cie.2020.106273

Salmasnia, A., & Talesh-Kazemi, A. (2022). Integrating inventory planning, pricing, and maintenance for perishable products in a two-component parallel manufacturing system with common cause failures. Operations Research International Journal, 22, 1235-1265. https://doi.org/10.1007/s12351-020-00590-6

San-José, L. A., Sicilia, J., González-de-la-Rosa, M., & Febles-Acosta, J. (2023). Profit maximization in an inventory system with time-varying demand, partial backordering and discrete inventory cycle. Annals of Operations Research, 316, 763-783. https://doi.org/10.1007/s10479-021-04161-6

Sarfaraz, A. H., Yazdi, A. K., Hanne, T., Wanke, P. F., & Hosseini, R. S. (2023). Assessing repair and maintenance efficiency for water suppliers: a novel hybrid USBM-FIS framework. Operations Management Research. https://doi.org/10.1007/s12063-023-00347-2

Sarhadi, R., & Asraei, A. (2021). Improving Inventory and Logistics Management Using Business Intelligence Ghiyath al-Din Jamshid Kashani University].

Shahrjerdi, R. (2022). A Framework for Evaluating Maintenance Systems Performance in Water and Wastewater Companies: A Case Study of Alborz Province Water and Wastewater Company. Water and Wastewater Science and Engineering, 7(4), 47-59.

Shirzadi, F., & Tavakkolan, M. (2022). A Decision Support System Model for Enhancing Maintenance Management of Equipment Based on Augmented Reality Considering Maintenance Priorities University of Tehran].

Silva, J. A. (2023). Wastewater treatment and reuse for sustainable water resources management: a systematic literature review. Sustainability, 15(14), 10940-10940. https://doi.org/10.3390/su151410940

Sitompul, E., & Rohmat, A. (2021). IoT-based running time monitoring system for machine preventive maintenance scheduling. Elkha Jurnal Teknik Elektro (Pontianak), 13(1), 33-40. https://doi.org/10.26418/elkha.v13i1.44202

Taheri, M. T., Maki Al Agha, M., & Samadiyar, H. (2022). Prioritizing and managing industrial waste in the ninth refinery of South Pars Gas Complex. Environmental and Water Engineering, 8(4), 842-855. https://www.jewe.ir/article_146971_c5df0e9b2abce6eb1af1e8d80c4a8780.pdf?lang=en

Wang, C., Lu, Z., & Yu, J. (2025). Biological Optimization of Sustainable Agricultural Systems Through Genetic Algorithms and Nitrogen Balance Management. Molecular & Cellular Biomechanics, 22(3), 1073. https://doi.org/10.62617/mcb1073

Wang, R., Cheng, Z., Dong, E., Guo, C., & Rong, L. (2021). Reliability-based opportunistic maintenance modeling for multi-component systems with economic dependence under base warranty. Discrete Dynamics in Nature and Society, 52, 1-16. https://doi.org/10.1155/2021/5541902

Wang, W., Chen, Y., Wang, Y., Deveci, M., Cheng, S., & Brito-Parada, P. R. (2024). A decision support framework for humanitarian supply chain management – Analysing enablers of AI-HI integration using a complex spherical fu zzy DEMATEL-MARCOS method. Technological Forecasting and Social Change, 206, 123556. https://doi.org/10.1016/J.TECHFORE.2024.123556

Xie, S., Lim, Y. T., Wang, H., Yi, W., & Antwi-Afari, M. F. (2024). Location and Capacity Optimization of Waste Recycling Centers: Mathematical Models and Numerical Experiments. Applied Sciences, 14(16), 7039-7039. https://doi.org/10.3390/app14167039

Yang, W., Baji, H., & Li, C. Q. (2020). A Theoretical Framework for Risk-Cost-Optimized Maintenance Strategy for Structures. International Journal of Civil Engineering, 18, 261-278. https://doi.org/10.1007/s40999-019-00470-x

Zhang, J., Du, D., Si, X., Hu, C., & Zhang, H. (2021). Joint optimization of preventive maintenance and inventory management for standby systems with hybrid-deteriorating spare parts. Reliability Engineering and System Safety, 214. https://doi.org/10.1016/j.ress.2021.107686

Zhang, Q., Xu, S., & Miao, K.-X. (2024). Research on Global Illegal Wildlife Trade Based on Integrated Optimization Methodologies. Highlights in Science Engineering and Technology, 115, 230-236. https://doi.org/10.54097/r0v6np04

Downloads

Published

Submitted

Revised

Accepted

Issue

Section

License

Copyright (c) 2024 Meysam Salavati (Author); Hossein Adab; Ahmadreza Kasraei, Jalal Haghight Monfard (Author)

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.